| |

|

.

Proactive Die, Mold, and Tooling Specialists

Over 25 years of experience in die materials, metallurgy, and manufacturing make Badger Metal Tech the reliable resource for die and mold maintenance. North American Manufacturing relies on Badger Metal Tech to provide comprehensive "Preventative Maintenance Programs" for die casting,

blanking/stamping (HSLA applications), and draw forming dies (HSLA

applications). Maximizing tooling life and enhancing performance are one of the keys to controlling costs and saving energy.

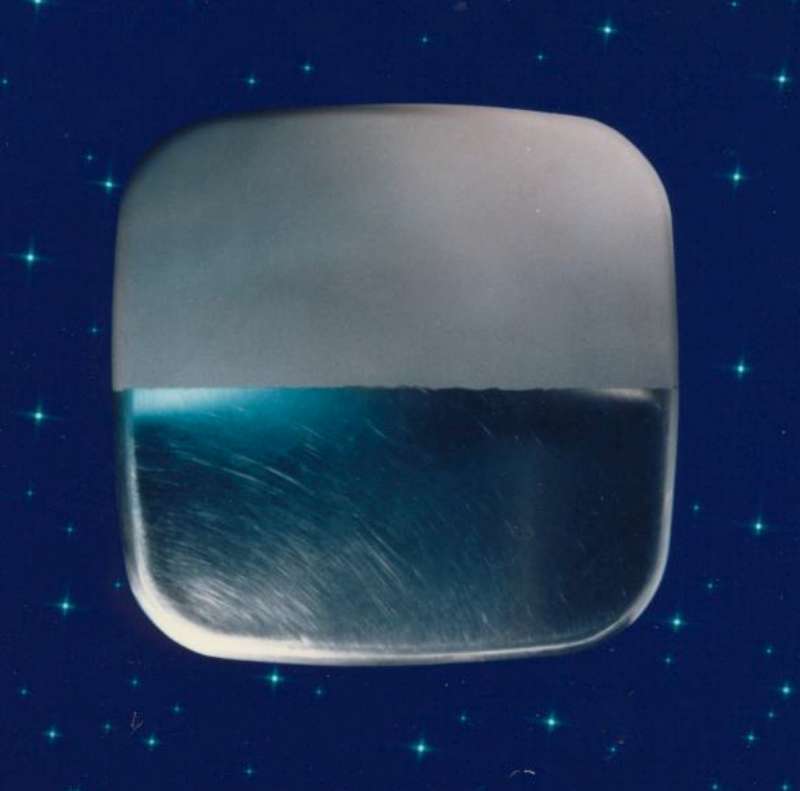

Why draw polish?

(click on photo)

top half

MetaLLife processed - no

more draw polish stress risers

click to view this photos full size and see difference

Using the latest in application technology,

MetaLLife

and

TherMaLLife are

the most cost effective surface treatments that are used extensively in the tooling industry for proactive and reactive die maintenance.

These processes can be applied separately or in combination (TooLLife)

to provide the many needed benefits that extend and improve tooling

performance.

Mission Statement

Badger Metal Tech is committed to providing, in a timely manner, proprietary quality unique surface treatments that improve the performance and extend the life of die casting tools as well as enhancing the performance of all other types of perishable tooling, including drawing/ forming/

blanking/stamping dies, and plastic molds. We work closely as free consultants having over 25 years of direct experience helping customers find ways to reduce tooling costs while creating higher quality products for OEM’s.

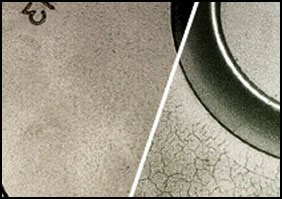

Not processed

After 72,000 shots |

Processed New and at 50K

After 119,000 shots |

| |

|

|

|

|

DIE SURFACE ENGINEERING

DIE CASTING DIES

PREVENT AND REPAIR FAILURES...REDUCE CASTING COST

AND IMPROVE PERFORMANCE.

NEW TOOLING

Draw Polish Stress Risers Shorten Die Casting Tooling Life

Draw polishing has been used for decades to help with the

release of castings and to help the aluminum alloy to flow better over flat

surfaces. What wasn't understood, however, was the effect the stoning

(cutting edges) is having on the surface of the steel. The fact is, draw

polishing acutely cuts stress risers into the casting surface of the steel.

These stress risers often lead to aiding the start of the most frustrating

issue a die caster has with tool life...heat checking, cracking, and

possible cavitation breakout in certain affected areas.

Javascript DHTML Drop Down Menu Powered by dhtml-menu-builder.com

USED TOOLING

After and Before

MetaLLife die

treatment

Send us castings to receive

Free Quotes & Consulting

within 24 hrs

DRAWING

FORMING BLANKING TOOLS

STOP DRAW FORMING GALLING AND PICKUP AND INCREASE THE FATIGUE STRENGTH

OF STAMPING DIES AND PUNCHES

Send us parts

prints that show

desired process areas to

receive a Free Quote within 24 hrs

|

|

|